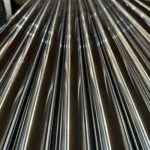

4140 Chrome Plated Rod

4140 hard chrome plated bar: High strength alloy steel for critical applications

4140 Hard Chrome Plated Bar is a high performance steel bar made from SAE 4140, an alloy known for its excellent strength and durability. Our factory is a leading supplier of 4140 Chrome Plated bars in China, offering a wide range of sizes from 6mm to 760mm (1/4″ to 30″) in diameter for industries that demand precision, reliability and superior surface finish.

What is 4140 steel?

4140 steel, also known as 42CrMo in China, is a versatile alloy structural steel that conforms to the AISI standard. Containing elements such as chromium, molybdenum and manganese, it is renowned for its toughness, high tensile strength and exceptional resistance to impact and abrasion. Due to its excellent forgeability, machinability and heat treatability, 4140 steel is widely used in the manufacturing, construction and oil and gas industries.

The steel is commonly used in the manufacture of gears, shafts, bolts, drill collars, tool joints and other machine components. In addition, 4140 steel is essential for high-stress, high-impact parts such as hydraulic cylinder rods, pneumatic cylinder rods, eccentric shafts and crankshafts used in heavy-duty machinery.

For more details or to place an order, please contact us for expert advice on selecting the right specifications for your projects.

Free Quote

Our 4140 Chrome Plated Rods are manufactured from high quality SAE 4140 steel bars which are then precision ground using centreless grinding to ensure a flawless finish. These bars are then chrome plated with a coating ranging from 20 microns (0.0008 inches) to 25 microns (0.001 inches), providing excellent corrosion resistance and a bright, reflective surface. This chrome plating is not just for aesthetics – its primary function is to increase the wear resistance and durability of the rod, making it ideal for hydraulic and pneumatic applications.

Product Details | Description |

Product Name | SAE 4140 Hard Chrome Plated Rod |

Manufacturer Name | Myler |

Origin | Wuxi, China |

Material | SAE 4140 / AISI 4140 / 4140 |

Size Range | Dia. 6 mm – Dia. 760 mm (1/4 inch to 30 inch) |

Tolerance | ISO f7, h8, g6 (on request) |

Length | Random length & cut length, max. length up to 12m |

Surface Roughness | Max Ra 0.2 μm |

Chrome Plated Thickness | Min. 20 microns, 25 microns, 30 microns, 50 microns |

Surface Hardness | Min. 900 HV |

Packing Method | Supplied in cardboard tubes for protection on outer surface, then packed in wooden cases |

Chrome Plating Function | Provides excellent corrosion resistance and a reflective surface, increasing wear resistance & durability |

Delivery Conditions | – Hard Chrome Piston Rod (HRC 15-20) |

Chemical Composition of SAE 4140 Chrome Plated Rod (for Shafts)

Element | Min (%) | Max (%) |

Carbon (C) | 0.36 | 0.44 |

Silicon (Si) | 0.10 | 0.40 |

Manganese (Mn) | 0.65 | 1.10 |

Phosphorus (P) | – | 0.04 |

Sulfur (S) | – | 0.04 |

Chromium (Cr) | 0.75 | 1.20 |

Molybdenum (Mo) | 0.15 | 0.35 |

Mechanical Properties of SAE 4140 Chrome Plated Rod

Property | Value |

Yield Strength | Min. 800 MPa / 115K psi |

Tensile Strength | Min. 900 MPa / 130K psi |

Elongation | Min. 20% |

Hardness (HB) | Min. 270 HB |

Diameter Tolerance

Diameter Range | Tolerance (mm) | Tolerance (Inches) |

Up to 51mm Dia (Up to 2.0 inches) | +0.00, -0.025 | +0.00, -0.001 |

Over 51mm – 102mm Dia (Over 2.0 – 4.0 inches) | +0.00, -0.050 | +0.00, -0.002 |

Over 102mm Dia (Over 4.0 inches) | +0.00, -0.075 | +0.00, -0.003 |

Straightness Tolerance

Diameter | Straightness Tolerance |

Below 50mm | 0.25mm per 1000mm |

Over 50mm | 0.30mm per 1000mm |

Hard Chrome Plating Specifications

Property | Value |

Typical Surface Hardness | HV 1000 – 1150 |

Typical Surface Roughness | 0.10 – 0.30 μm Ra (Microns) |

Typical Surface Deposit | 0.025 – 0.050 mm (0.001″ – 0.002″) |

Features of 4140 steel

- High fatigue strength

- Resistant to notching and cracking

- Excellent low temperature impact toughness

- Resistant to temper embrittlement

- Ideal for high load applications

Due to its balanced properties, 4140 is primarily used in the quenched and tempered condition for the manufacture of parts subject to high impact or fatigue loads, including forging dies, hydraulic rods and industrial machinery components.

Applications for 4140 Chrome Plated Rods

- Hydraulic Systems: For use in hydraulic cylinders, rods and pistons that must withstand high pressure and stress.

- Pneumatic systems: Essential for pneumatic cylinder rods to ensure smooth operation and durability.

- Industrial Machinery: Ideal for components subject to constant friction and mechanical stress.

- Automotive and Manufacturing: Used in heavy-duty components such as suspension systems, gears and shafts.

- Oil and Gas Industry: Used in critical parts such as drill collars and heavy equipment components.

With its superior mechanical properties, 4140 chrome bars are sought after by the hydraulic, automotive, pneumatic and manufacturing industries for applications requiring high performance, durability and precision. Whether you are looking for corrosion resistant components for your hydraulic cylinders or a reliable part for heavy machinery, 4140 chrome rod is the solution for demanding environments.

Frequently Asked Questions

Question 1: What is the lead time for chrome plated rods?

Answer: As a leading chrome plated rod manufacturer and supplier, we maintain a large inventory of various sizes and materials. Typically, our delivery time is 10–20 days, depending on the quantity and specifications. Contact us for a quick quote tailored to your needs!

Question 2: How do you ensure the quality of your hard chrome plated rods?

Answer: We implement a strict Total Quality Management System in our factory. We source raw materials (round steel bars) from top-tier Chinese steel makers like TPCO, Sha-Steel, and Huaigang Special Steel. Each chrome plated rod is inspected before packing and comes with a mill test certificate (EN 10204/3.1). Quality and reliability are our priorities.

Question 3: Are you a manufacturer or a trading company?

Answer: We are a professional chrome plated rod manufacturer based in Wuxi, Jiangsu, China. With years of experience in producing chrome plated bars and hydraulic cylinder tubes, we welcome customers to visit our factory and see our production process firsthand.

Question 4: How do you protect chrome plated rods during transportation?

Answer: To ensure the outer surface of the chrome plated rods remains undamaged, we pack each rod in a paper tube (cardboard sleeve) and then secure them in wooden cases. This method guarantees safe delivery to your location.

Question 5: Do you export chrome plated rods? What are your main markets?

Answer: Yes, as one of the largest chrome plated rod suppliers in China, we export to numerous countries worldwide. Our primary markets include the USA, Vietnam, Australia, Russia, UAE, Canada, South Africa, Thailand, and Brazil. Let us know your requirements, and we’ll provide a competitive quote!

Question 6: Will chrome plated steel bars rust?

Answer: Chrome plated steel bars are highly resistant to rust due to the protective chrome layer. However, if the plating is damaged, the underlying steel may corrode over time. Proper handling and maintenance can extend their lifespan significantly.

Custom Solutions & Competitive Pricing

Ready to Order or Have More Questions?

If you’re looking for high-quality chrome plated rods for your industrial needs, we’re here to help! As a trusted manufacturer and wholesale supplier, we offer customizable solutions and competitive pricing. Send us your inquiry today, and let’s discuss how we can meet your requirements!