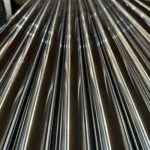

Chrome Rod

Durable Chrome Rods - Manufacturer & Custom Wholesale Options

We produce and supply high-quality chrome rods for industrial use. Whether you need standard sizes or custom specifications, we offer flexible wholesale and manufacturing solutions. Get in touch for a quote tailored to your requirements.

Want to buy wholesale chrome rods?

- Contact: shanks

- Tel: (86) 17766334294

- Email: info@chromerods.com

- Whatsapp:(86)17766334294

Free Quote

Chrome Plated Bars: Product Overview

Product Standards Our chrome-plated bars are crafted to meet precise customer specifications and adhere to the following standards:

- ASTM A311

- ASTM A108

- Other recognized industry standards

Steel Grades Available

Our hard chrome-plated shafts are available in the following steel grades:

- SAE 1045 Carbon Steel

- CK45 / C45 Carbon Steel

- Stainless Steel (available upon request)

Chrome Bar Size Range

- Metric Sizes: External diameter ranging from 6 mm to 900 mm

- Imperial Sizes: Available from 1/4″ to 32″

Length Options for Chrome Plated Bars

We offer flexibility in lengths for our hydraulic cylinder chrome rods, available in both random and fixed lengths, tailored to customer specifications.

- Maximum available length: 12 meters

Diameter Tolerance of Chrome Plated Bars

Our chrome-plated bars are manufactured with the following diameter tolerances:

- ISO f7, f8, g6

- Custom tolerances upon request

Surface Finish

The surface roughness of our chrome-plated rods meets industry standards:

- Ra 0.2μm (8 Ra) average, with a maximum of Ra 0.4μm (16 Ra)

Hard Chrome Plating Thickness

The chrome plating on our hydraulic cylinder rods typically has a minimum thickness of 20 microns (0.0008 inches), with options for thicker coatings upon request.

- Maximum thickness: 50 microns

Our chrome bars are rigorously tested to withstand a 48-hour salt spray test in accordance with ASTM B-117 standards, ensuring high durability and corrosion resistance.

Packaging

To protect the surface quality during handling, transportation, and delivery, our chrome plated shafts are securely packaged in cardboard tubes.

Customization Options

- Custom diameters and chrome plating thicknesses available

- Option for Hardened Induction Heat Treatment for added strength (available on request)

At Myler, we are a leading chrome rod manufacturer specialising in the production of high quality precision chrome rods for various industrial applications. As a trusted chrome rod supplier, we offer a wide range of industrial chrome rods and hydraulic chrome rods designed for heavy duty and precision engineering needs. Whether you’re looking for OEM Chrome Rods, Custom Chrome Rods or Customised Chrome Rod Solutions, we’ll meet all your requirements with the utmost attention to detail.

As an established chrome rod factory, we offer both wholesale chrome rods and bulk chrome rod wholesale options, ensuring cost effective solutions for companies of all sizes. Our products are available for immediate delivery, with Chrome Rods in stock and ready to ship worldwide. With years of experience as a Chrome Rod Exporter and Global Chrome Rod Distributor, we serve customers across the globe, offering competitive Chrome Rod prices and Chrome Rod quotes upon request.

We pride ourselves in providing durable Chrome Rods, known for their reliability and resistance to wear, making them ideal for use in Chrome Rods for hydraulic cylinders, automotive, machinery, and other heavy duty applications. Our products are also ISO compliant, ensuring the highest standards of quality.

In addition, we offer Chrome Rod technical support and expert solutions to assist in selecting the right Chrome Rods for machinery and other application specific needs. From high precision chrome rod manufacturers to heavy duty chrome rods, we supply reliable and high quality products for every industry requirement.

For enquiries please contact us today and explore how our Certified Chrome Rod Manufacturer services can meet your needs.

Hard chrome plated shafts: Material and Mechanical Properties

As a leading manufacturer and supplier of chrome-plated bars, we meet a wide range of customer requirements by offering high quality bars in medium carbon steel grades. The most commonly used steel grades for our chrome shafts include

- SAE 1045

- CK45

- SAE 4140

- 42CrMo

- JIS S45C

- DIN CK45

Of these, SAE 1045 and CK45 are the most popular choices due to their excellent balance of strength and machinability.

Chemical composition of SAE 1045 / CK45 steels

Steel Grade | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

SAE 1045 | 0.43 – 0.50 | 0.60 – 0.90 | – | ≤0.040 | ≤0.050 |

CK 45 | 0.42 – 0.50 | 0.50 – 0.80 | ≤0.40 | ≤0.035 | ≤0.035 |

Chemical Composition of SAE 4140 Chrome Plated Bar

Element | Min (%) | Max (%) |

Carbon (C) | 0.36 | 0.44 |

Silicon (Si) | 0.10 | 0.40 |

Manganese (Mn) | 0.65 | 1.10 |

Phosphorus (P) | – | 0.04 |

Sulfur (S) | – | 0.04 |

Chromium (Cr) | 0.75 | 1.20 |

Molybdenum (Mo) | 0.15 | 0.35 |

Mechanical properties of chrome plated shafts

Steel Grade | Yield Strength | Tensile Strength | Elongation | Hardness |

SAE 1045 | 75,000 psi (517 MPa) | 85,000 psi (585 MPa) | 10% | Rc 60-72 |

CK 45 | 75,000 psi (517 MPa) | 85,000 psi (585 MPa) | 10% | Rc 60-72 |

SAE 4140 | 115,000 psi (800 MPa) | 130,000 psi (900 MPa) | 20% | HB 270 |

Our chrome bars can be heat treated to a minimum yield strength of 100,000 psi (690 MPa), making them ideal for high performance applications. For industries requiring high strength components, we recommend SAE 4140 hard chrome shafts, which offer superior mechanical properties.

Applications

- Hydraulic Cylinder rods

- Heavy Equipment shafts

- CNC Chrome Plated Rods

- High Tensile Steel Rods

- Corrosion Stainless Steel Rods

- OEM Spares

Our chrome plated shafts are ideal for hydraulic systems, automotive applications, industrial machinery and precision machining. Custom diameters, chrome thicknesses and additional heat treatments are available on request to meet your specific requirements.

Let us know if you’d like to explore other material options or require further details on MOQ, custom specifications or certifications.

Chrome Plated Piston Rod Dimensions

Diameter (Inches) | Weight per Foot (Lbs.) | Diameter (mm) | Weight per Meter (KG.) |

0.375 | 0.375 | 10 | 0.62 |

0.438 | 0.512 | 12 | 0.89 |

0.5 | 0.668 | 14 | 1.21 |

0.625 | 1.043 | 15 | 1.39 |

0.688 | 1.264 | 16 | 1.58 |

0.75 | 1.502 | 17 | 1.78 |

0.875 | 2.044 | 18 | 2 |

0.938 | 2.349 | 20 | 2.47 |

1 | 2.67 | 22 | 2.98 |

1.063 | 3.017 | 25 | 3.85 |

1.125 | 3.379 | 28 | 4.83 |

1.188 | 3.768 | 30 | 5.55 |

1.25 | 4.172 | 32 | 6.31 |

1.313 | 4.603 | 35 | 7.55 |

1.375 | 5.048 | 36 | 7.99 |

1.5 | 6.008 | 40 | 9.86 |

1.563 | 6.523 | 45 | 12.48 |

1.625 | 7.05 | 50 | 15.41 |

1.688 | 7.608 | 55 | 18.65 |

1.75 | 8.177 | 56 | 19.33 |

1.875 | 9.387 | 60 | 22.19 |

1.938 | 10.028 | 63 | 24.47 |

2 | 10.68 | 65 | 26.05 |

2.125 | 12.057 | 70 | 30.21 |

2.25 | 13.517 | 75 | 34.68 |

2.375 | 15.06 | 80 | 39.46 |

2.5 | 16.688 | 85 | 44.54 |

2.625 | 18.398 | 90 | 49.94 |

2.75 | 20.192 | 95 | 55.64 |

2.875 | 22.069 | 100 | 61.65 |

3 | 24.03 | 105 | 67.97 |

3.25 | 28.202 | 110 | 74.6 |

3.375 | 30.413 | 115 | 81.53 |

3.5 | 32.708 | 120 | 88.78 |

3.625 | 35.085 | 125 | 96.33 |

3.75 | 37.547 | 130 | 104.19 |

4 | 42.72 | 140 | 120.83 |

4.25 | 48.227 | 150 | 138.71 |

4.5 | 54.068 | 160 | 157.82 |

4.75 | 60.242 | 170 | 178.17 |

5 | 66.75 | 180 | 199.75 |

5.25 | 73.592 | 200 | 246.6 |

5.5 | 80.768 | 250 | 385.31 |

6 | 96.12 | 150 | 284.61 |

6.5 | 112.808 | 165 | 332.75 |

7 | 130.83 | 180 | 387.02 |

7.5 | 150.188 | 200 | 453.45 |

8 | 170.88 | 220 | 510.87 |

8.5 | 192.908 | 230 | 541.18 |

9 | 216.27 | 250 | 590.96 |

10 | 267 | 270 | 726.85 |

11 | 323.07 | 280 | 847.46 |

12 | 384.48 | 300 | 973.72 |

Tolerance for Chrome Shafts (ISO 286-2)

Diameter Range (mm) | d9 | e8 | f7 | g6 | h5 | h6 | h7 | h8 | h9 | h11 |

0 – 3 | -20 | -14 | -6 | -2 | 0 | 0 | 0 | 0 | 0 | 0 |

3 – 6 | -30 | -20 | -10 | -4 | 0 | 0 | 0 | 0 | 0 | 0 |

6 – 10 | -40 | -25 | -13 | -5 | 0 | 0 | 0 | 0 | 0 | 0 |

10 – 18 | -50 | -32 | -16 | -6 | 0 | 0 | 0 | 0 | 0 | 0 |

18 – 30 | -65 | -40 | -20 | -7 | 0 | 0 | 0 | 0 | 0 | 0 |

30 – 50 | -80 | -50 | -25 | -9 | 0 | 0 | 0 | 0 | 0 | 0 |

50 – 65 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

65 – 80 | -100 | -60 | -30 | -10 | 0 | 0 | 0 | 0 | 0 | 0 |

80 – 100 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

100 – 120 | -120 | -72 | -36 | -12 | 0 | 0 | 0 | 0 | 0 | 0 |

120 – 140 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

140 – 160 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

160 – 180 | -145 | -85 | -43 | -14 | 0 | 0 | 0 | 0 | 0 | 0 |

180 – 200 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

200 – 225 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

225 – 250 | -170 | -100 | -50 | -15 | 0 | 0 | 0 | 0 | 0 | 0 |

250 – 280 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

280 – 315 | -190 | -110 | -56 | -17 | 0 | 0 | 0 | 0 | 0 | 0 |

315 – 355 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

355 – 400 | -210 | -125 | -62 | -18 | 0 | 0 | 0 | 0 | 0 | 0 |

Advantages of Our Premium Chrome Plated Steel Bars for Hydraulic Cylinders

Our factory’s chrome-plated piston rods are engineered to deliver unmatched performance in hydraulic systems, combining precision engineering with advanced material science. Here’s why global customers prioritize our products:

1. Dimensional Accuracy

Our chrome rods are manufactured with ultra-tight tolerances (±0.01mm), ensuring seamless integration with hydraulic cylinder components. This precision minimizes friction, optimizes sealing efficiency, and reduces downtime during assembly.

2. High-Grade Carbon & Alloy Steel Composition

Crafted from premium-grade SAE 1045/4140/4340 steel, our bars achieve an optimal balance of tensile strength (up to 100,000 psi yield strength) and machinability. This material selection enhances weldability, fatigue resistance, and load-bearing capacity for heavy-duty applications.

3. Advanced Hard Chrome Plating Technology

Featuring a multi-layer electroplating process, our rods achieve a uniform chromium coating (20-50μm thickness) with micro-crack resistance. This results in a mirror-like finish (Ra ≤0.2μm) for reduced friction, paired with exceptional corrosion resistance in harsh environments like marine or chemical industries.

4. Surface Hardness & Wear Resistance

With a hardened surface layer exceeding HV850 (Rockwell HRC 65+), our chrome-plated bars outperform standard hydraulic rods in abrasive conditions. This extreme hardness extends service life by 40-60% compared to uncoated alternatives, reducing replacement costs and maintenance intervals.

5. Customized Heat Treatment Solutions

Through controlled quenching and tempering processes, we optimize core toughness (impact strength up to 25J) while maintaining surface integrity. This dual-phase structure prevents brittle fracture in high-pressure hydraulic systems operating at 3000+ psi.

6. Value-Added Benefits for OEMs

Reduced total cost of ownership through extended MTBF (mean time between failures)

Compliance with ISO 286-2 tolerance standards and ASTM A519 material specifications

Available in polished, ground, or honed finishes for specialized sealing requirements

Ideal for excavator rams, injection molding machines, and industrial automation systems, our chrome-plated bars are the engineered solution for demanding hydraulic applications requiring reliability, longevity, and precision motion control.

Applications of Chrome Plated Bars

Chrome plated bars are critical components in many industrial applications, particularly in hydraulic and pneumatic systems, where they serve as a primary material for piston rods. Beyond this core function, their versatility and superior surface properties make them suitable for a wide array of additional uses across different sectors.

Due to their excellent wear resistance, corrosion protection, and precise dimensional accuracy, chrome plated bars are widely utilized in industries where mechanical integrity and operational reliability are paramount.

1. Hydraulic and Pneumatic Systems

In fluid-driven systems, such as those used in heavy machinery or aerospace equipment, chrome-plated bars are integral for creating the high-performance shafts and pistons required to withstand tough conditions. These bars ensure prolonged service life by resisting wear, corrosion, and fatigue, ensuring efficient operation in applications like construction equipment and industrial machinery.

2. Material Handling Systems

Chrome plated bars enhance material handling systems like conveyors, cranes, and lifting mechanisms. With a smooth finish that reduces friction and a high tensile strength, they are perfect for systems moving large and heavy objects, commonly seen in manufacturing, logistics, and even mining operations.

3. Automation and Robotics

In the field of robotics, chrome plated bars are favored for their ability to maintain precision and durability under constant mechanical motion. They are used in robotic arms and automation systems that require highly accurate movements and long-lasting performance, particularly in industries like electronics and automotive assembly.

4. Machinery and Industrial Equipment

Chrome plated bars are a vital component in machines that face high operational stress, such as presses, stamping machines, and die-casting equipment. Their resistance to wear and tear makes them a reliable choice for ensuring the longevity and performance of industrial machinery working under high pressure.

5. Automotive Components

The automotive industry uses chrome plated bars for producing suspension systems, shock absorbers, and steering mechanisms, where the bars’ resistance to wear, corrosion, and environmental factors is essential. These components contribute to the overall durability and safety of vehicles, especially in demanding driving conditions.

6. Pumps, Compressors, and Power Systems

In sectors such as oil and gas, water treatment, and energy production, chrome plated bars are essential for manufacturing pumps, compressors, and other power-generating equipment. Their corrosion-resistant properties allow these critical systems to function optimally, even in harsh operational environments.

7. Aerospace and Aviation

Chrome plated bars are crucial in aerospace technology, used in actuators, control rods, and structural components that must endure extreme conditions. Their exceptional strength and ability to resist high temperatures and mechanical stresses are key for ensuring the safety and reliability of flight systems.

8. Construction and Heavy Equipment

In the construction and mining industries, chrome plated bars are found in heavy-duty machinery like excavators, drills, and hydraulic arms. Their hard-wearing surface makes them ideal for withstanding the harsh environments and demanding workloads typically encountered in these sectors.

Frequently Asked Questions

Question 1: What is the lead time for chrome plated rods?

Answer: As a leading chrome plated rod manufacturer and supplier, we maintain a large inventory of various sizes and materials. Typically, our delivery time is 10–20 days, depending on the quantity and specifications. Contact us for a quick quote tailored to your needs!

Question 2: How do you ensure the quality of your hard chrome plated rods?

Answer: We implement a strict Total Quality Management System in our factory. We source raw materials (round steel bars) from top-tier Chinese steel makers like TPCO, Sha-Steel, and Huaigang Special Steel. Each chrome plated rod is inspected before packing and comes with a mill test certificate (EN 10204/3.1). Quality and reliability are our priorities.

Question 3: Are you a manufacturer or a trading company?

Answer: We are a professional chrome plated rod manufacturer based in Wuxi, Jiangsu, China. With years of experience in producing chrome plated bars and hydraulic cylinder tubes, we welcome customers to visit our factory and see our production process firsthand.

Question 4: How do you protect chrome plated rods during transportation?

Answer: To ensure the outer surface of the chrome plated rods remains undamaged, we pack each rod in a paper tube (cardboard sleeve) and then secure them in wooden cases. This method guarantees safe delivery to your location.

Question 5: Do you export chrome plated rods? What are your main markets?

Answer: Yes, as one of the largest chrome plated rod suppliers in China, we export to numerous countries worldwide. Our primary markets include the USA, Vietnam, Australia, Russia, UAE, Canada, South Africa, Thailand, and Brazil. Let us know your requirements, and we’ll provide a competitive quote!

Question 6: Will chrome plated steel bars rust?

Answer: Chrome plated steel bars are highly resistant to rust due to the protective chrome layer. However, if the plating is damaged, the underlying steel may corrode over time. Proper handling and maintenance can extend their lifespan significantly.

Custom Solutions & Competitive Pricing

Ready to Order or Have More Questions?

If you’re looking for high-quality chrome plated rods for your industrial needs, we’re here to help! As a trusted manufacturer and wholesale supplier, we offer customizable solutions and competitive pricing. Send us your inquiry today, and let’s discuss how we can meet your requirements!