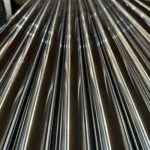

CK45 Chrome Plated Bar

CK45 Chrome Plated Bar | Precision Hydraulic Cylinder Rods Manufacturer

As a leading manufacturer of industrial chrome rods, we specialize in producing premium CK45 chrome plated bars from 6mm to 900mm diameters. Our hard chrome plated rods combine exceptional strength with superior surface finishes, making them ideal for hydraulic systems and heavy-duty industrial applications.

What is CK45 Chrome Plated Rod?

The CK45 chrome plated rod is also known as CK45 chrome bar or CK45 steel rod. This product is a medium-tensile carbon steel bar made from CK45 material, precision manufactured and then subjected to hard chrome plating. It is widely used in the production of hydraulic cylinder rods, making it commonly referred to as CK45 hydraulic piston rod or CK45 hydraulic cylinder rod.

Free Quote

CK45 Chrome Bar Production Details

The CK45 chrome bars produced by our factory are available in a wide range of metric and inch sizes.

Diameter: 10 mm to 900 mm (metric)

Imperial inch size: 3/8″ to 36″ Material Specifications: Made from high-quality CK45 ultra-hard chromium steel, the bars meet strict international material standards. Internal and external screw threads are available as per customer requirements.

Length Options:

Our factory offers CK45 chrome bars in random lengths or cut-to-length options. The maximum length available can reach up to 15 meters (metric) depending on the specific application needs.

Application Fields:

These CK45 chrome bars are widely used in hydraulic cylinders, mechanical devices, and various engineering applications requiring high-strength materials.

Special Services:

Custom cutting services are available upon request to meet precise requirements for length and thread configurations.

Why Choose CK45 Chrome Plated Rod?

High Tensile & Yield Strength: Ensures long-lasting durability and structural integrity.

Hard Chrome Plating: Provides exceptional wear resistance and extended service life.

Precision Manufacturing: Processed to tight tolerances, ensuring exact fits for various applications.

International Standard Compliance: Meets DIN EN 10083-1 standards, ensuring quality and reliability.

Quality Control & Certification

Our CK45 chrome plated rods undergo stringent quality control measures, including:

- Precision grinding and polishing before plating.

- Hard chrome plating to specific thickness and finish requirements.

- Final inspection to ensure compliance with international standards.

Contact Us for More Information

If you are interested in our CK45 chrome plated bars or require detailed technical specifications, please feel free to reach out to us.

For inquiries or wholesale orders, email: info@chromerods.com| Tel: (86)17766334294

1. Chemical Composition

Element | Content Range (%) |

Carbon (C) | 0.42 – 0.50 |

Manganese (Mn) | 0.50 – 0.80 |

Silicon (Si) | 0.40 Max |

Phosphorus (P) | 0.035 Max |

Sulfur (S) | 0.035 Max |

2. Mechanical Properties

Property | Value |

Yield Strength | 75 Kpsi / 517 MPa |

Tensile Strength | 85 Kpsi / 585 MPa |

Elongation | 10% |

Hardness (Rockwell Scale) | Rc 60-72 |

Tolerance (ISO 286-2 Standard):

The following tolerance table is based on ISO 286-2 standards for CK45 chrome rods:

Diameter Range (d) | Upper Tolerance (e) | Lower Tolerance (h) |

d9 | +3 mm | -60 mm |

d10 | +6 mm | -76 mm |

d11 | +10 mm | -93 mm |

d12 | +18 mm | -117 mm |

d13 | +30 mm | -142 mm |

d14 | +50 mm | -174 mm |

d15 | +65 mm | -191 mm |

d16 | +80 mm | -207 mm |

d17 | +100 mm | -226 mm |

d18 | +120 mm | -245 mm |

d19 | +140 mm | -266 mm |

d20 | +160 mm | -280 mm |

d21 | +180 mm | -291 mm |

d22 | +200 mm | -307 mm |

d23 | +225 mm | -320 mm |

d24 | +250 mm | -340 mm |

d25 | +280 mm | -356 mm |

d26 | +315 mm | -372 mm |

d27 | +350 mm | -398 mm |

d28 | +400 mm | -416 mm |

Tolerance Explanation:

- d: Diameter range (in millimeters)

- e: Upper tolerance limit

- h: Lower tolerance limit

- The “+”sign indicates allowable deviation, while the “-“ sign indicates unacceptable deviation.

Surface Condition: Chrome Plating and Finishing

Property | Specification |

Chrome Plating Thickness | – Minimum: 20 microns (0.0008 inches) or 25 microns (0.001 inches) |

| – Maximum: Up to 50 microns |

| – Custom thickness options available based on specific requirements |

Salt Spray Testing | – Minimum of 48 hours compliance with ASTM B-117 standards, ensuring superior corrosion resistance |

Surface Roughness (Ra) | – Approximately 0.2 μm (8 Ra) maximum, up to 0.4 μm (16 Ra) |

Surface Finish | Ensures optimal performance in high-stress mechanical environments |

Material Grade: CK45 (Equivalent to SAE 1045)

Tensile Strength: 670-800 Mpa

Yield Strength: ~520 Mpa (75 Ksi)

Applications: Hydraulic cylinders, pumps, mechanical machinery, construction equipment, and fluid power systems

CK45 chrome plated bar Application areas

- Mechanical components: bearings, gears, transmissions, etc.

- Construction materials: for pipes, building materials, etc.

- Tool making: Suitable for less complex tools and parts.

Frequently Asked Questions

Question 1: How to ensure the quality of CK45 chrome plated bars?

During the production process, advanced heat treatment technology is used to ensure that the chrome plating is uniform and free of defects.

Each batch of products undergoes strict quality inspection and performance testing to meet international standards.

Question 2: What is the delivery lead time?

The production lead time for CK45 chrome plated bars is usually 2-3 weeks, depending on the order quantity and customer’s customised requirements. We can provide flexible delivery programme according to customer’s requirement.

Question 3: Is the supply chain stable?

Our supply chain is strictly managed, and we work with several reliable steel suppliers with back-up plans to ensure the continuity of raw material supply.

Question 4: How cost-effective is it?

CK45 chrome plated bar has a high cost, but its excellent performance makes it often save maintenance and replacement cost in the long run. We can provide customised quotations to ensure optimum economy.

Question 5: What about environmental protection and compliance?

The production process strictly complies with environmental protection regulations and uses low-pollution, high-efficiency production processes to ensure that there is no negative impact on the environment. We can provide detailed compliance documents to meet customer needs.

Question 6: How about technical support and service?

We have a professional technical support team ready to solve installation, maintenance or other problems for our customers. We provide comprehensive after-sales service to ensure that the products are guaranteed in every aspect of use.

Question 7: Can CK45 chrome plated bar be customised?

Yes, we customise according to customer’s special requirements, such as surface treatment, cicada lying process, etc., to meet different application scenarios. Please let us know your specific requirements and we will try our best to co-operate with you.

Custom Solutions & Competitive Pricing

Ready to Order or Have More Questions?

If you’re looking for high-quality chrome plated rods for your industrial needs, we’re here to help! As a trusted manufacturer and wholesale supplier, we offer customizable solutions and competitive pricing. Send us your inquiry today, and let’s discuss how we can meet your requirements!